-

Used Fasti 215-32-6 Panel Bender

This Fasti panel bender is under power, bending parts, and in good used condition. Bends up to 7 gauge material. Great opportunity to get into a panel bender for low investment. Includes one set of tooling. Equipped with FM 200 control. 127.5″ overall length.

-

Used Swiss Machines Available Now

2016 GENTURN SL-42Y28 AXIS HYBRID SWISS MACHINESMITSUBISHI M830 CNC CONTROL2 Machines Availble3 Bank Axial Live ToolChip Conveyor and CartSpindle Chiller $119,990/each with 30 day parts warranty MINT CONDITION 2016 GANESH CYCLONE 52 BY2“B” Axis with 12 Live Tools, Dual “Y” Axis, Parts Catcher, Chip Conveyor, Mistbuster 850 Oil Filtration, Spindle Chiller, Cutting Oil Chiller, 36…

-

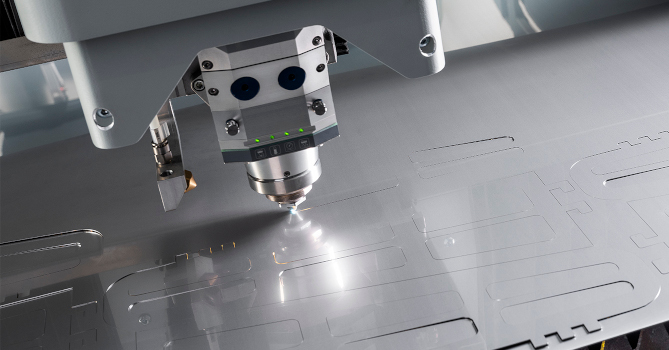

Cutting Metal with Fiber Lasers: Understanding the Pros and Cons of Different Assist Gases for Carbon Steel, Stainless Steel, and Aluminum

Cutting metal with a fiber laser requires an assist gas to blow away molten material and debris. Oxygen is commonly used for cutting carbon steel due to its ability to quickly react with iron, resulting in a faster cutting speed. However, oxygen can cause oxidation and dross formation, which can lower the quality of the…

-

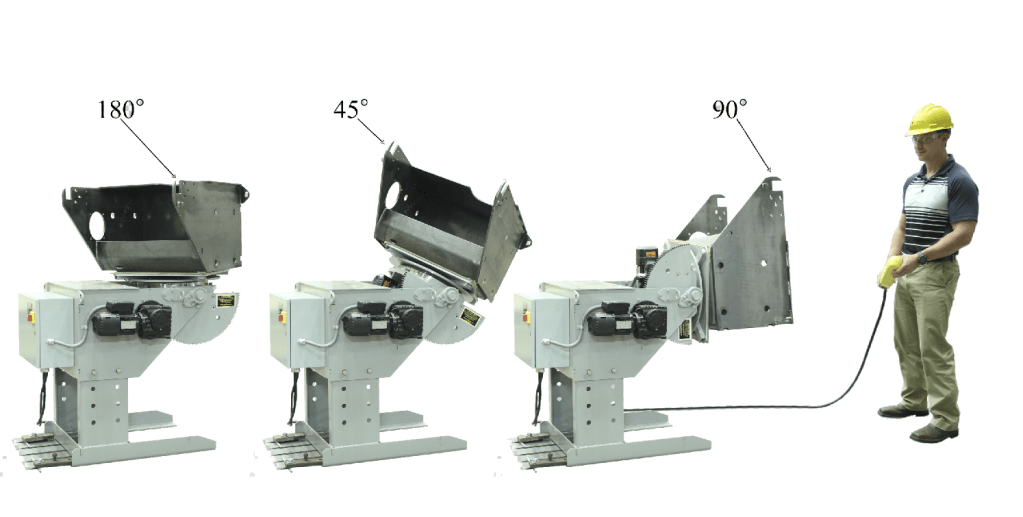

Boost Welding Efficiency and Quality with Koike Aronson Welding Positioners

Looking for a reliable and efficient welding positioner to increase productivity and improve weld quality? Look no further than Koike Aronson’s welding positioners. We understand that every welding job is unique. That’s why we offer a wide range of welding positioners to fit your specific needs; gear driven rotary tables, turning rolls, headstocks and tailstocks,…

-

Optimizing Laser Cutting Operations with Nitrogen Generation and High Pressure Dry Air Systems

Nitrogen generation and high pressure dry air systems are two options that laser cutting operators can choose from to improve their cutting processes. Nitrogen generators are commonly used as assist gases in laser cutting operations due to their ability to produce high-quality cuts and reduce oxidation. They work by filtering atmospheric air to produce high-purity…

-

Why Your Fabrication Job Shop Should Consider a 6-10kW Laser for Cutting Efficiency

When a fabrication job shop is considering purchasing a new laser, it is important to carefully evaluate the power requirements needed to meet the demands of the shop’s production needs. In many cases, a laser with a power output between 6-10kw is ideal for most job shop applications. Firstly, a laser with a power output…

-

Used Dener Puma XL 40×220 For Sale

For sale is a Dener Puma XL press brake, which is just over a year old and in excellent working condition. This machine has a capacity of 4 meters x 242 US Tons, making it ideal for handling larger metal fabrication jobs. It is equipped with a 4-axis back gauge, ESA 675 control, and laser…

-

Dener Press Brakes: The Affordable and Versatile Solution for Your Metal Fabrication Needs

Dener press brakes have earned a reputation as being some of the best value options on the market, and for good reason. They offer both hydraulic and electric options, making them versatile enough to fit into any metal fabrication shop’s workflow. Dener press brakes are known for their robust construction, durability, and precision, all while…

-

Streamlining Your Metal Fabrication or Machine Shop: The Benefits of Implementing Lean Manufacturing Principles

Lean manufacturing is a philosophy that aims to eliminate waste in all forms and optimize the entire production process to increase efficiency, reduce costs, and improve quality. For metal fabrication and machine shops, implementing lean manufacturing principles can offer several benefits that can make their business more competitive and profitable. One of the main benefits…

-

The Advantages of Owning a Tube Laser in Your Metal Fabrication Shop

Metal fabrication shops are increasingly turning to tube lasers for cutting, drilling, and slotting of various metals. Here are eight reasons why a metal fabrication shop should own a tube laser: In conclusion, a tube laser can be a valuable addition to many metal fabrication shops. With its versatility, speed, cost savings, consistent quality, reduced…

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.